Li-screw tsa Konkreite tsa Hlooho e Tšoeu ea Zinki e Tšoeu

Kopo

Leha Dikurufu tsa Konkreite tse Tshehla tsa Zinc tse nang le hlooho e oval di loketse konkreite le ditshebediso tse ding tsa majwe, di boetse di loketse ho sebediswa lehong le tshepeng. Dikurufu tsena di phethahetse bakeng sa ho tiisa ntho efe kapa efe ho tloha ho dikoung le terata ho ya marulelong a tshepe le siding. Di boetse di ntle bakeng sa ho kgomaretsa thepa ya ka ntle, disebediswa tsa mabone le dintho tse ding ka mokhoa o sireletsehileng fatshe. Ka lebaka la matla a tsona a ikgethang le ho tshwarella, dikurufu tsena di ka sebediswa ditshebedisong tse nang le kgatello e phahameng moo di-fasteners tse ding di ka hlolehang.

Tšobotsi

Ntle le matla a tsona a phahameng le ho tšoarella, Li-screw tsa Konkreite tsa Zinc Yellow tse nang le hlooho e oval li na le likarolo tse 'maloa tsa bohlokoa tse etsang hore li feto-fetohe haholo le ho ba bonolo ho li sebelisa. Qetello ea mosehla oa zinc e etselitsoe ho fihlela kapa ho feta maemo a indasteri bakeng sa ho hanyetsa mafome, ho netefatsa hore li-screw tsena li tla mamella maemo a leholimo ka lilemo tse tlang. Moralo oa hlooho e oval e tlaase o boetse o etsa hore ho be bonolo ho khanna li-screw sebakeng sa tsona ho sebelisoa drill ea motlakase e tloaelehileng kapa screwdriver. Qetellong, li-screw tsena li fumaneha ka boholo le bolelele bo fapaneng, e leng se etsang hore ho be bonolo ho fumana se loketseng morero ofe kapa ofe.

Likarolo tsa Lintho tse bonahalang

| Sus | C | Si | Mn | P | S | Ni | Cr | Mo | Cu |

| 304 | 0.08 | 1.00 | 2.00 | 0.045 | 0.027 | 8.0-10.5 | 18.0-20.0 | 0.75 | 0.75 |

| 304Hc | 0.08 | 1.00 | 2.00 | 0.045 | 0.028 | 8.5-10.5 | 17.0-19.0 |

| 2.0-3.0 |

| 316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.029 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | 0.75 |

| 430 | 0.12 | 0.75 | 1.00 | 0.040 | 0.030 |

| 16.0-18.0 |

|

Mefuta ea Lithapo bakeng sa Linaha tse Fapaneng

| mm | CN.WG | SWG | BWG | JOALOKA.WG |

| 1G |

|

| 7.52 | 7.19 |

| 2G |

|

| 7.21 | 6.67 |

| 3G |

|

| 6.58 | 6.19 |

| 4G |

|

| 6.05 | 5.72 |

| 5G |

|

| 5.59 | 5.26 |

| 6G | 5.00 | 4.88 | 5.16 | 4.88 |

| 7G | 4.50 | 4.47 | 4.57 | 4.50 |

| 8G | 4.10 | 4.06 | 4.19 | 4.12 |

| 9G | 3.70 | 3.66 | 3.76 | 3.77 |

| 10G | 3.40 | 3.25 | 3.40 | 3.43 |

| 11G | 3.10 | 2.95 | 2.05 | 3.06 |

| 12G | 2.80 | 2.64 | 2.77 | 2.68 |

| 13G | 2.50 | 2.34 | 2.41 | 2.32 |

| 14G | 2.00 | 2.03 | 2.11 | 2.03 |

| 15G | 1.80 | 1.83 | 1.83 | 1.83 |

| 16G | 1.60 | 1.63 | 1.65 | 1.58 |

| 17G | 1.40 | 1.42 | 1.47 | 1.37 |

| 18G | 1.20 | 1.22 | 1.25 | 1.21 |

| 19G | 1.10 | 1.02 | 1.07 | 1.04 |

| 20G | 1.00 | 0.91 | 0.89 | 0.88 |

| 21G | 0.90 | 0.81 | 0.81 | 0.81 |

| 22G |

| 0.71 | 0.71 | 0.73 |

| 23G |

| 0.61 | 0.63 | 0.66 |

| 24G |

| 0.56 | 0.56 | 0.58 |

| 25G |

| 0.51 | 0.51 | 0.52 |

Manala a Moralo o Ikhethileng

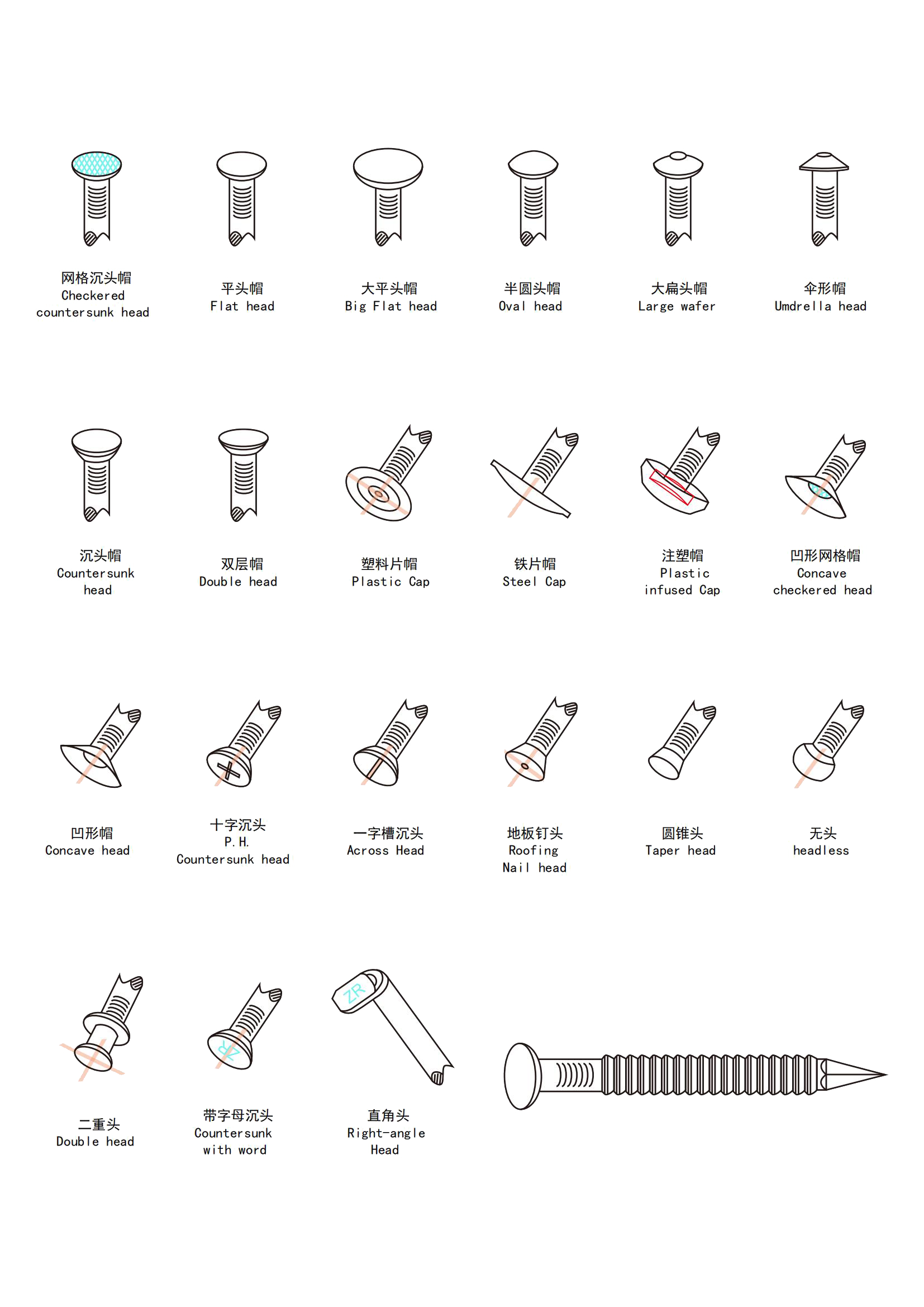

Mofuta le Sebopeho sa Hlooho ea Manala

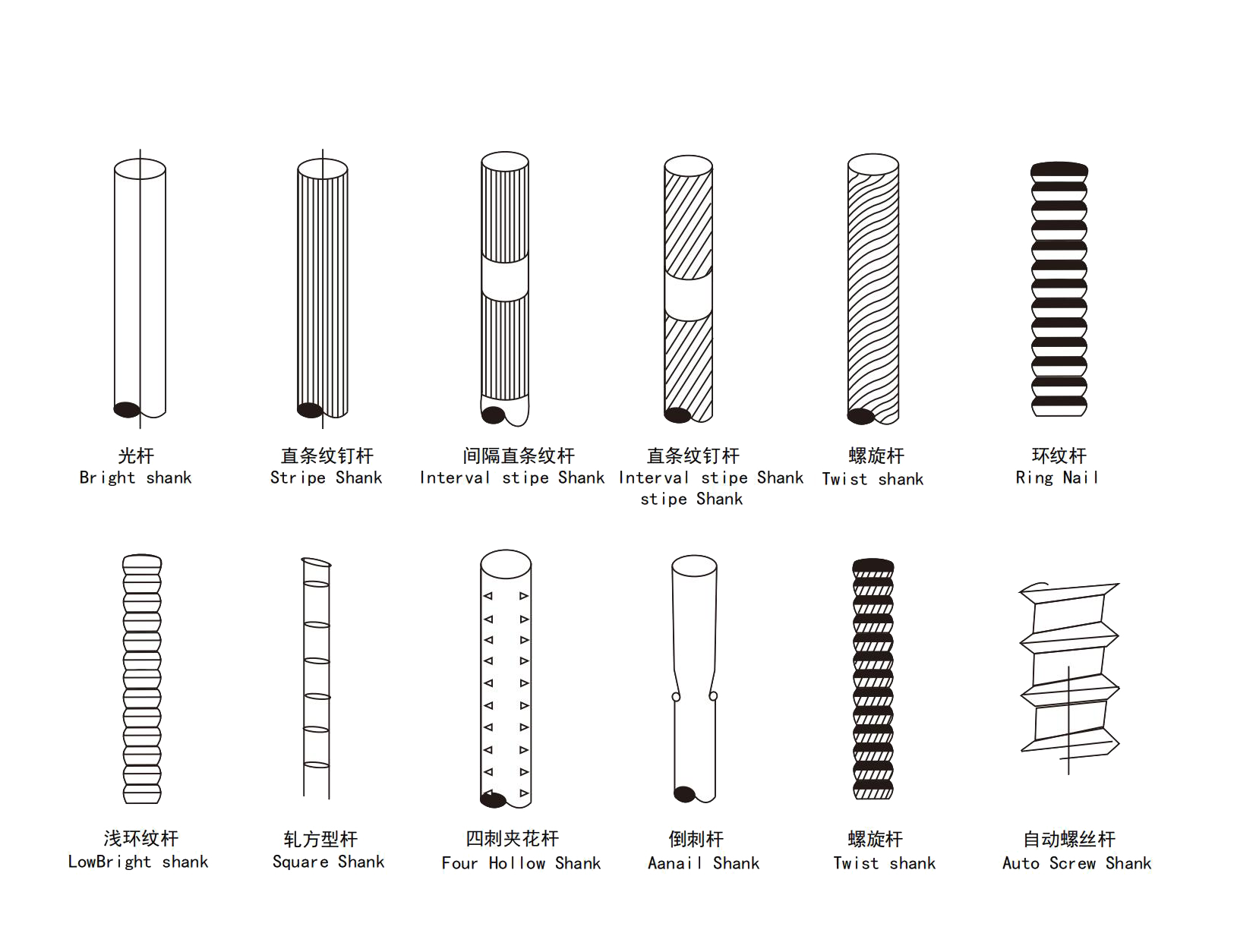

Mofuta le Sebopeho sa Sekotjana sa Manala

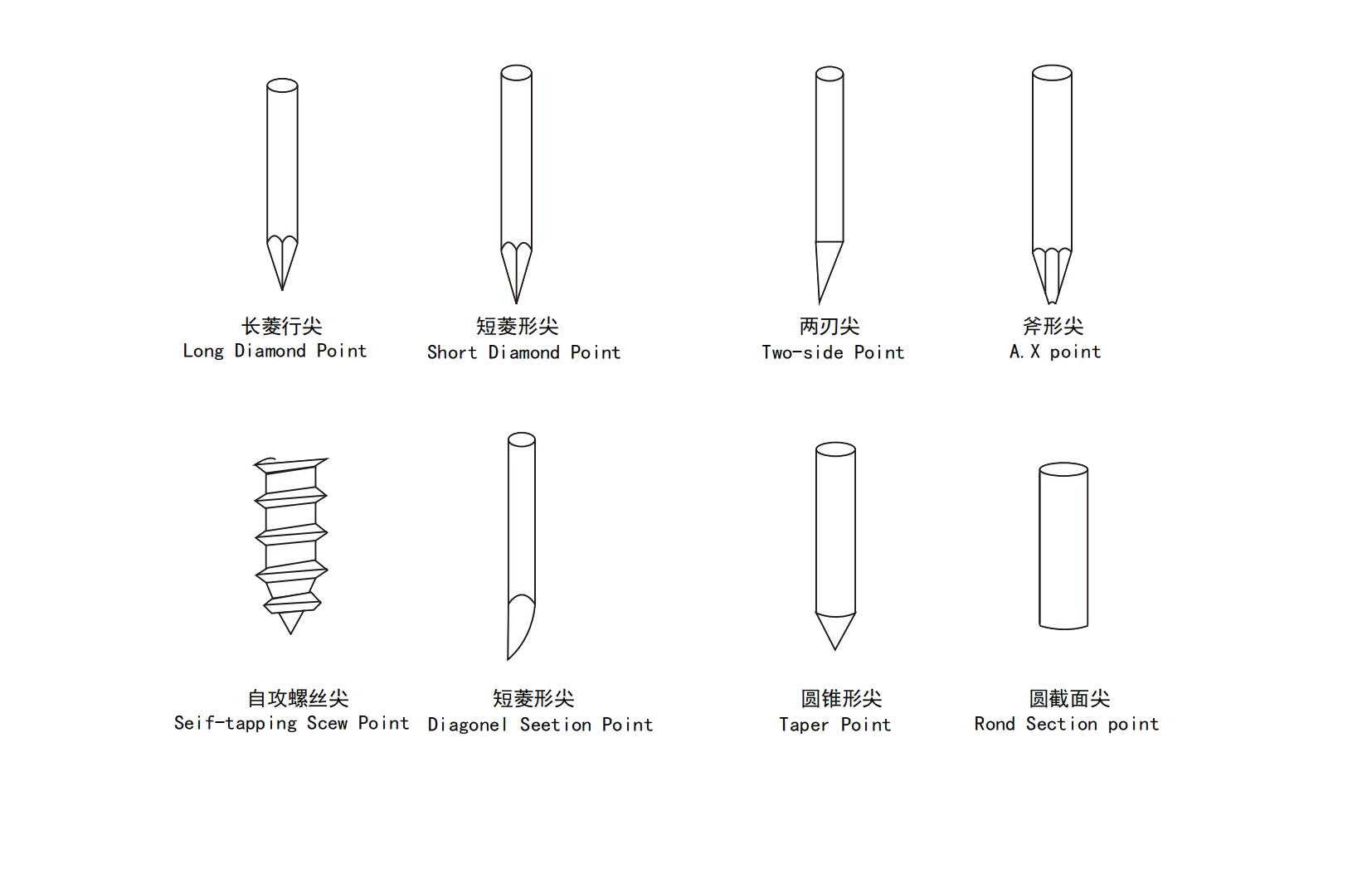

Mofuta le Sebopeho sa Manala Ntlha

Yihe Enterprise ke khamphani e ikgethileng ka moralo le tlhahiso ya manala, manala a sekwere, di-nail roll, mefuta yohle ya manala le di-screw tse bōpehileng ka tsela e ikgethang. Khetho ya di-nail tsa tshepe ya carbon ya boleng bo hodimo, koporo, aluminium le tshepe e sa ruseng, mme e ka etsa galvanized, hot dip, black, koporo le kalafo e nngwe ya bokahodimo ho ya ka tlhoko ya bareki. Sekuru se seholo ho hlahisa di-screw tsa mochini tse entsweng US ANSI, BS machine screw, bolt corrugated, ho kenyeletswa 2BA, 3BA, 4BA; di-screw tsa mochini tse entsweng Jeremane DIN (DIN84/ DIN963/ DIN7985/ DIN966/ DIN964/ DIN967); GB Series le mefuta e meng ya dihlahiswa tse tloaelehileng le tse sa tlwaelehang tse kang di-screw tsa mochini le mefuta yohle ya di-screw tsa mochini wa koporo.

Sehlahisoa sa rona se ka sebelisoa thepa ea ka tlung ea ofisi, indastering ea likepe, tereneng, kahong, indastering ea likoloi. Ka lits'ebetso tse pharaletseng tse loketseng mafapha a fapaneng, sehlahisoa sa rona se ikhetha ka boleng ba sona bo ikhethang—se entsoe ka thepa ea boleng bo holimo le mekhoa e tsoetseng pele ea tlhahiso ho netefatsa ho tšoarella le ts'ebetso e ntle ka ho fetisisa. Ho feta moo, re boloka thepa e ngata ka linako tsohle, e le hore u ka natefeloa ke ho tlisoa kapele le ho qoba tieho mererong ea hau kapa ts'ebetsong ea khoebo, ho sa tsotelehe bongata ba odara.

Ts'ebetso ea rona ea tlhahiso e hlalosoa ke boqhetseke bo botle haholo—e tšehelitsoe ke theknoloji e tsoetseng pele le litsebi tsa mesebetsi ea matsoho tse nang le boiphihlelo, re ntlafatsa mohato o mong le o mong oa tlhahiso ho netefatsa ho nepahala le bokhabane sehlahisoa se seng le se seng. Re tiisa melaoana e thata ea taolo ea boleng e sa sieeng sebaka sa ho sekisetsa: thepa e tala e hlahlojoa ka hloko, litekanyetso tsa tlhahiso li behiloe leihlo haufi-ufi, 'me lihlahisoa tsa ho qetela li hlahlojoa ka botlalo ka boleng. Re susumetsoa ke boinehelo ba bokhabane, re loanela ho etsa lihlahisoa tsa boleng bo holimo tse hlahelletseng 'marakeng ka boleng ba tsona bo phahameng le boleng bo tšoarellang nako e telele.