Manala a Koili ea Ring Shank Pallet

Kopo

Lipekere tsa pallet ea ring shank li sebelisoa haholo indastering e mengata, haholo-holo kahong le mosebetsing oa mapolanka. Li loketse ho tiisa li-pallet, mabokose, thepa ea marulelo, li-subfloor le likarolo tse ling tsa sebopeho, lipekere tsena li fana ka ho tšoara le matla a sa bapisoeng le a sa tloaelehang. Moralo oa ring shank o thibela lipekere ho hlepha kapa ho khutlela morao, ho netefatsa botšepehi ba thepa e khomaretsoeng nako e telele. Ebang u haha deck, u kenya subfloor, kapa u haha foreimi ea lehong, lipekere tsa pallet ea ring shank ke khetho e tšepahalang ea ho tiisa projeke ea hau ka kholiseho.

Tšobotsi

1. Matla a Phahameng a ho Tšoara: Ka lebaka la sebopeho sa tsona sa lesale shank, manala ana a fana ka matla a ikhethang a ho tšoara, a fetang a manala a boreleli a shank. Masale a tšoara likhoele tsa lehong ka katleho, a fokotsa menyetla ea ho hula le ho theha khokahano e tiileng.

2. Ho tšoarella: Lipekere tsa coil tsa ring shank pallet tse entsoeng ka tšepe ea boleng bo holimo li tšoarella haholo ebile li hanela ho kobeha kapa ho sotha. Ho tšoarella hona ho netefatsa hore lipekere li khona ho mamella meroalo e boima le likarolo tse thata ntle le ho beha tšebetso ea tsona kotsing.

3. Ho kenya ka Bokgoni: Sebopeho sa koili sa manala ana se dumella ho kenya ka bokgabane ka hara dithunya tsa manala. Sena se fedisa tlhoko ya ho kenya hape kgafetsa, ho boloka nako le ho eketsa tlhahiso nakong ya tshebetso ya ho tiisa.

4. Ho feto-fetoha ha maemo: Lipekere tsa pallet tsa ring shank li fumaneha ka bolelele le litekanyo tse fapaneng, li loketse lits'ebetso le thepa e fapaneng. Ho feto-fetoha hona ho netefatsa hore ho na le boholo bo loketseng tlhoko e 'ngoe le e 'ngoe e itseng, e lumellang liphetho tse ntle tsa ho tiisa.

Likarolo tsa Lintho tse bonahalang

| Sus | C | Si | Mn | P | S | Ni | Cr | Mo | Cu |

| 304 | 0.08 | 1.00 | 2.00 | 0.045 | 0.027 | 8.0-10.5 | 18.0-20.0 | 0.75 | 0.75 |

| 304Hc | 0.08 | 1.00 | 2.00 | 0.045 | 0.028 | 8.5-10.5 | 17.0-19.0 |

| 2.0-3.0 |

| 316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.029 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | 0.75 |

| 430 | 0.12 | 0.75 | 1.00 | 0.040 | 0.030 |

| 16.0-18.0 |

|

Mefuta ea Lithapo bakeng sa Linaha tse Fapaneng

| mm | CN.WG | SWG | BWG | JOALOKA.WG |

| 1G |

|

| 7.52 | 7.19 |

| 2G |

|

| 7.21 | 6.67 |

| 3G |

|

| 6.58 | 6.19 |

| 4G |

|

| 6.05 | 5.72 |

| 5G |

|

| 5.59 | 5.26 |

| 6G | 5.00 | 4.88 | 5.16 | 4.88 |

| 7G | 4.50 | 4.47 | 4.57 | 4.50 |

| 8G | 4.10 | 4.06 | 4.19 | 4.12 |

| 9G | 3.70 | 3.66 | 3.76 | 3.77 |

| 10G | 3.40 | 3.25 | 3.40 | 3.43 |

| 11G | 3.10 | 2.95 | 2.05 | 3.06 |

| 12G | 2.80 | 2.64 | 2.77 | 2.68 |

| 13G | 2.50 | 2.34 | 2.41 | 2.32 |

| 14G | 2.00 | 2.03 | 2.11 | 2.03 |

| 15G | 1.80 | 1.83 | 1.83 | 1.83 |

| 16G | 1.60 | 1.63 | 1.65 | 1.58 |

| 17G | 1.40 | 1.42 | 1.47 | 1.37 |

| 18G | 1.20 | 1.22 | 1.25 | 1.21 |

| 19G | 1.10 | 1.02 | 1.07 | 1.04 |

| 20G | 1.00 | 0.91 | 0.89 | 0.88 |

| 21G | 0.90 | 0.81 | 0.81 | 0.81 |

| 22G |

| 0.71 | 0.71 | 0.73 |

| 23G |

| 0.61 | 0.63 | 0.66 |

| 24G |

| 0.56 | 0.56 | 0.58 |

| 25G |

| 0.51 | 0.51 | 0.52 |

Manala a Moralo o Ikhethileng

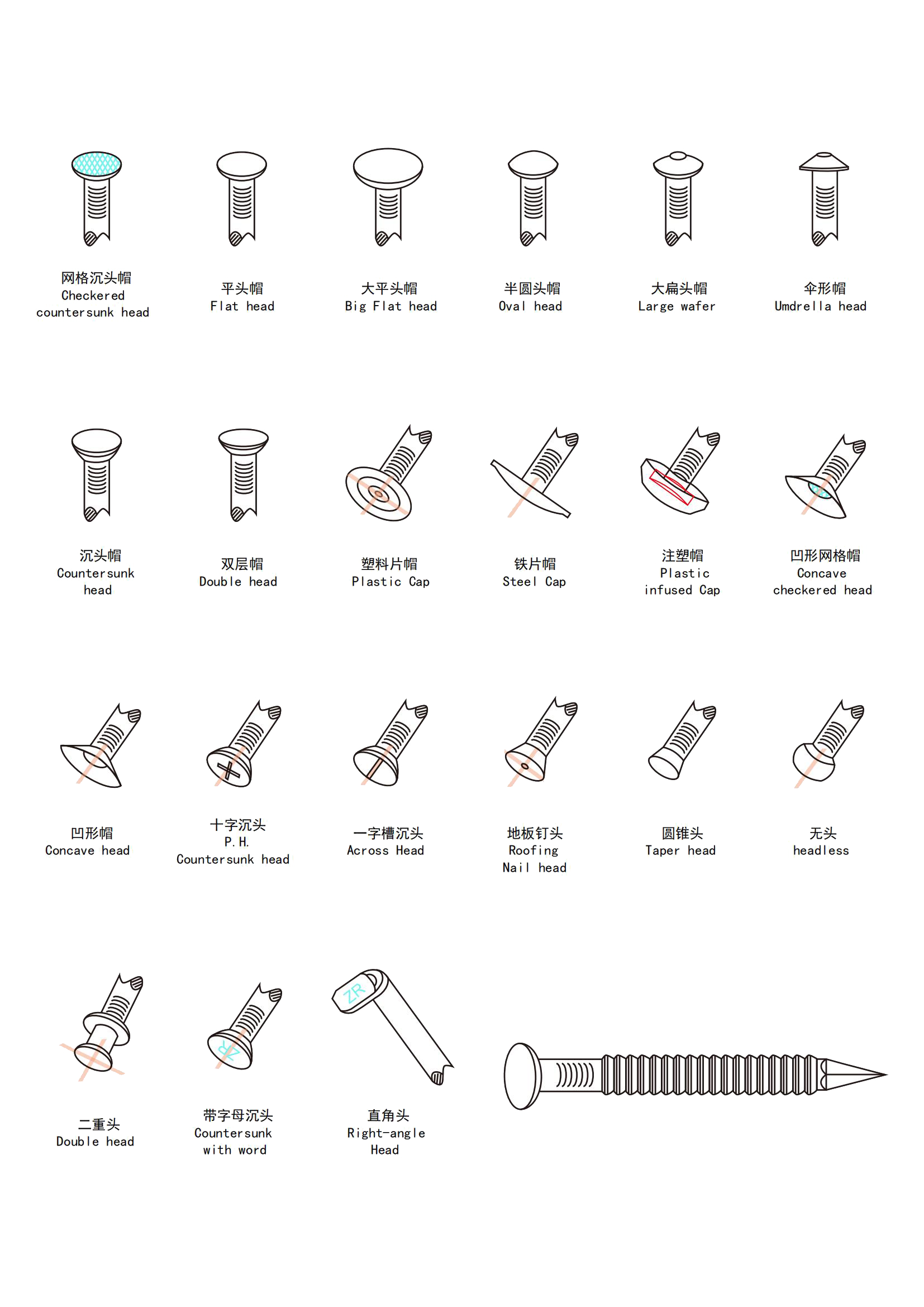

Mofuta le Sebopeho sa Hlooho ea Manala

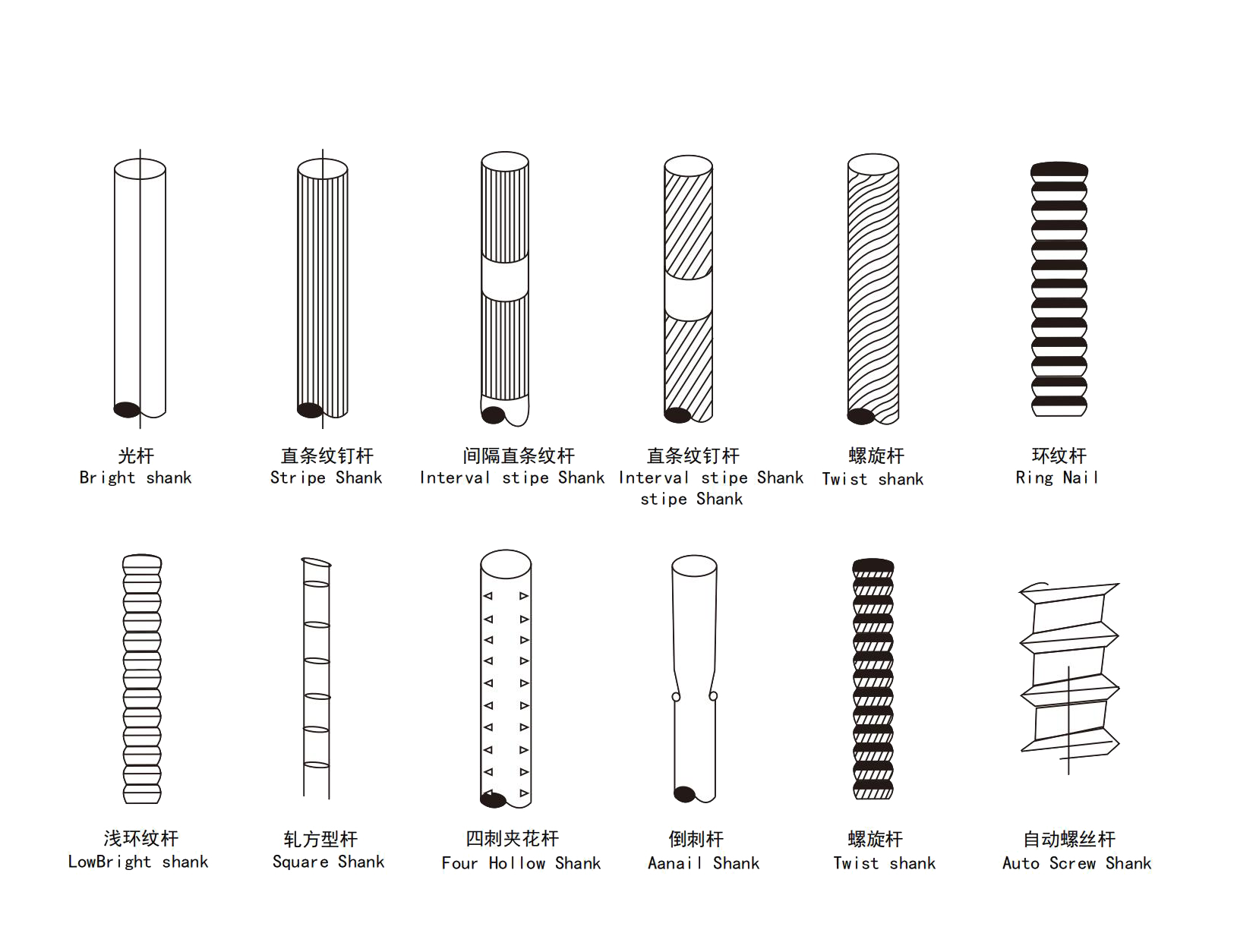

Mofuta le Sebopeho sa Sekotjana sa Manala

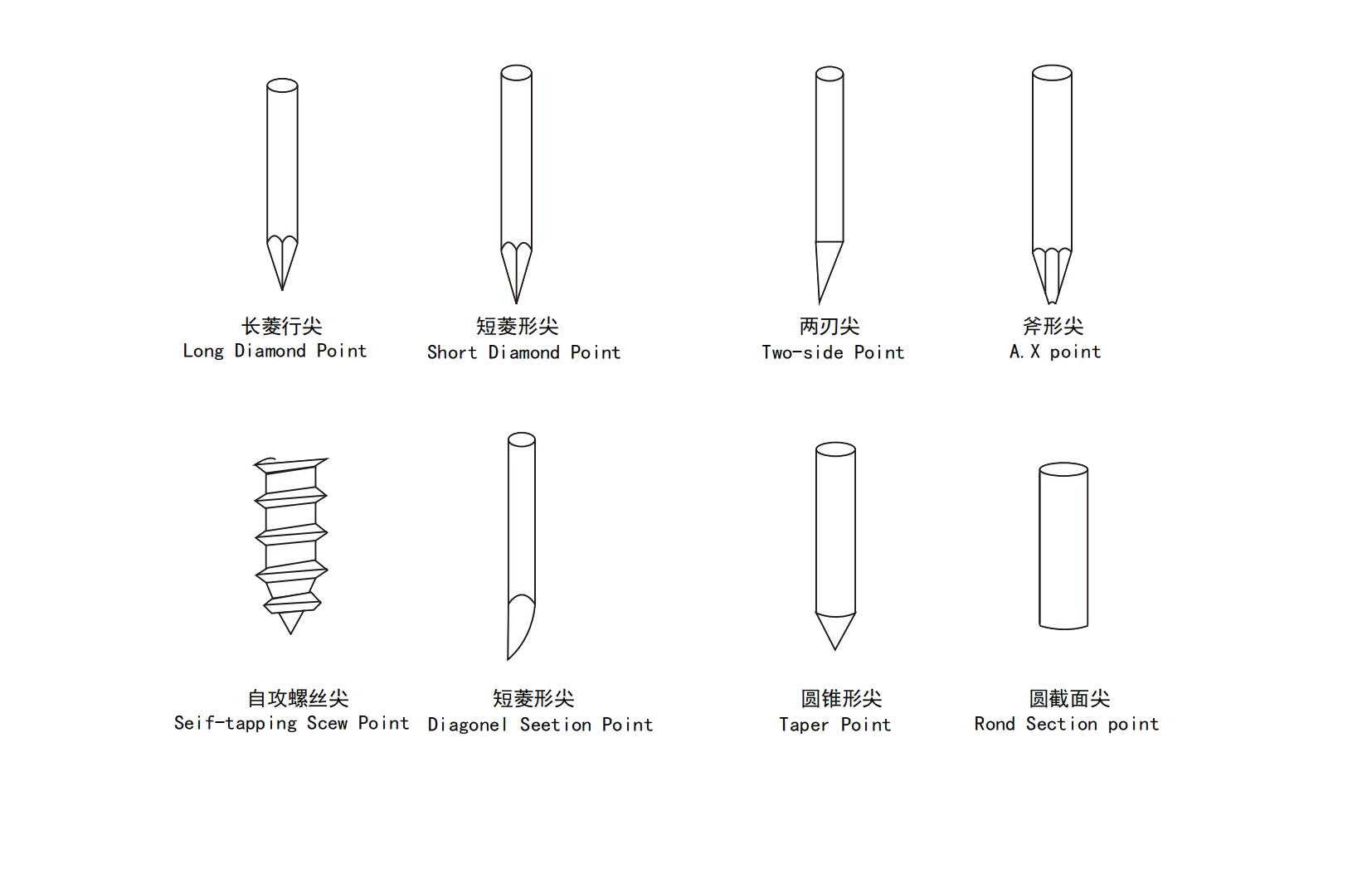

Mofuta le Sebopeho sa Manala Ntlha

Yihe Enterprise ke khamphani e ikgethileng ka moralo le tlhahiso ya manala, manala a sekwere, di-nail roll, mefuta yohle ya manala le di-screw tse bōpehileng ka tsela e ikgethang. Khetho ya di-nail tsa tshepe ya carbon ya boleng bo hodimo, koporo, aluminium le tshepe e sa ruseng, mme e ka etsa galvanized, hot dip, black, koporo le kalafo e nngwe ya bokahodimo ho ya ka tlhoko ya bareki. Sekuru se seholo ho hlahisa di-screw tsa mochini tse entsweng US ANSI, BS machine screw, bolt corrugated, ho kenyeletswa 2BA, 3BA, 4BA; di-screw tsa mochini tse entsweng Jeremane DIN (DIN84/ DIN963/ DIN7985/ DIN966/ DIN964/ DIN967); GB Series le mefuta e meng ya dihlahiswa tse tloaelehileng le tse sa tlwaelehang tse kang di-screw tsa mochini le mefuta yohle ya di-screw tsa mochini wa koporo.

Sehlahisoa sa rona se ka sebelisoa thepa ea ka tlung ea ofisi, indastering ea likepe, tereneng, kahong, indastering ea likoloi. Ka lits'ebetso tse pharaletseng tse loketseng mafapha a fapaneng, sehlahisoa sa rona se ikhetha ka boleng ba sona bo ikhethang—se entsoe ka thepa ea boleng bo holimo le mekhoa e tsoetseng pele ea tlhahiso ho netefatsa ho tšoarella le ts'ebetso e ntle ka ho fetisisa. Ho feta moo, re boloka thepa e ngata ka linako tsohle, e le hore u ka natefeloa ke ho tlisoa kapele le ho qoba tieho mererong ea hau kapa ts'ebetsong ea khoebo, ho sa tsotelehe bongata ba odara.

Ts'ebetso ea rona ea tlhahiso e hlalosoa ke boqhetseke bo botle haholo—e tšehelitsoe ke theknoloji e tsoetseng pele le litsebi tsa mesebetsi ea matsoho tse nang le boiphihlelo, re ntlafatsa mohato o mong le o mong oa tlhahiso ho netefatsa ho nepahala le bokhabane sehlahisoa se seng le se seng. Re tiisa melaoana e thata ea taolo ea boleng e sa sieeng sebaka sa ho sekisetsa: thepa e tala e hlahlojoa ka hloko, litekanyetso tsa tlhahiso li behiloe leihlo haufi-ufi, 'me lihlahisoa tsa ho qetela li hlahlojoa ka botlalo ka boleng. Re susumetsoa ke boinehelo ba bokhabane, re loanela ho etsa lihlahisoa tsa boleng bo holimo tse hlahelletseng 'marakeng ka boleng ba tsona bo phahameng le boleng bo tšoarellang nako e telele.