Manala a Konkreite a Hlooho e nang le Checkered Countersunk

Kopo

E 'ngoe ea lits'ebetso tsa mantlha tsa lipekere tsena ke bakeng sa mosebetsi oa ho etsa foreimi. Li bohlokoa haholo ha ho kenngoa li-stud kapa lihlooho maboteng a konkreite. Hlooho ea sepekere e nang le mapheo a masesaane e kenella ka botebo holim'a konkreite, e fana ka tšireletso e tiileng le e tšoarellang. Hape li ntle bakeng sa ho fanyeha lintho tse boima tse kang lishelefo, likhabote le liipone. Ka lipekere tsena, u ka kenya lintho habonolo leboteng la konkreite ntle le kotsi ea hore li oe kapa li robehe.

Tšobotsi

Lipekere tsena tsa konkreite le tsona ke khetho e ntle bakeng sa merero e mengata ea kaho. Li loketse ho lokisa lithaele tsa marulelo holim'a konkreite le ho kenya mapolanka a fatše holim'a fatše a konkreite. Ka matla a tsona a ho tšoara a phahameng, lipekere tsena li etsa bonnete ba hore ntho e 'ngoe le e 'ngoe e lula sebakeng sa eona e tiile ebile e sireletsehile. Tšobotsi e 'ngoe ea Lipekere tsa Konkreite tsa Checkered Countersunk Head ke hlooho ea tsona ea countersunk. Sena se bolela hore lihlooho tsa lipekere li qoelisoa hanyane holim'a konkreite, e leng se fanang ka qetello e boreleli le e se nang sekoli. Tšobotsi ena e ekelitsoeng ha e etse feela hore lipekere li shebahale li khahlisa ka botle empa hape e fokotsa kotsi ea ho khoptjoa ke lipekere tse hlahelletseng.

Likarolo tsa Lintho tse bonahalang

| Sus | C | Si | Mn | P | S | Ni | Cr | Mo | Cu |

| 304 | 0.08 | 1.00 | 2.00 | 0.045 | 0.027 | 8.0-10.5 | 18.0-20.0 | 0.75 | 0.75 |

| 304Hc | 0.08 | 1.00 | 2.00 | 0.045 | 0.028 | 8.5-10.5 | 17.0-19.0 |

| 2.0-3.0 |

| 316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.029 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | 0.75 |

| 430 | 0.12 | 0.75 | 1.00 | 0.040 | 0.030 |

| 16.0-18.0 |

|

Mefuta ea Lithapo bakeng sa Linaha tse Fapaneng

| mm | CN.WG | SWG | BWG | JOALOKA.WG |

| 1G |

|

| 7.52 | 7.19 |

| 2G |

|

| 7.21 | 6.67 |

| 3G |

|

| 6.58 | 6.19 |

| 4G |

|

| 6.05 | 5.72 |

| 5G |

|

| 5.59 | 5.26 |

| 6G | 5.00 | 4.88 | 5.16 | 4.88 |

| 7G | 4.50 | 4.47 | 4.57 | 4.50 |

| 8G | 4.10 | 4.06 | 4.19 | 4.12 |

| 9G | 3.70 | 3.66 | 3.76 | 3.77 |

| 10G | 3.40 | 3.25 | 3.40 | 3.43 |

| 11G | 3.10 | 2.95 | 2.05 | 3.06 |

| 12G | 2.80 | 2.64 | 2.77 | 2.68 |

| 13G | 2.50 | 2.34 | 2.41 | 2.32 |

| 14G | 2.00 | 2.03 | 2.11 | 2.03 |

| 15G | 1.80 | 1.83 | 1.83 | 1.83 |

| 16G | 1.60 | 1.63 | 1.65 | 1.58 |

| 17G | 1.40 | 1.42 | 1.47 | 1.37 |

| 18G | 1.20 | 1.22 | 1.25 | 1.21 |

| 19G | 1.10 | 1.02 | 1.07 | 1.04 |

| 20G | 1.00 | 0.91 | 0.89 | 0.88 |

| 21G | 0.90 | 0.81 | 0.81 | 0.81 |

| 22G |

| 0.71 | 0.71 | 0.73 |

| 23G |

| 0.61 | 0.63 | 0.66 |

| 24G |

| 0.56 | 0.56 | 0.58 |

| 25G |

| 0.51 | 0.51 | 0.52 |

Manala a Moralo o Ikhethileng

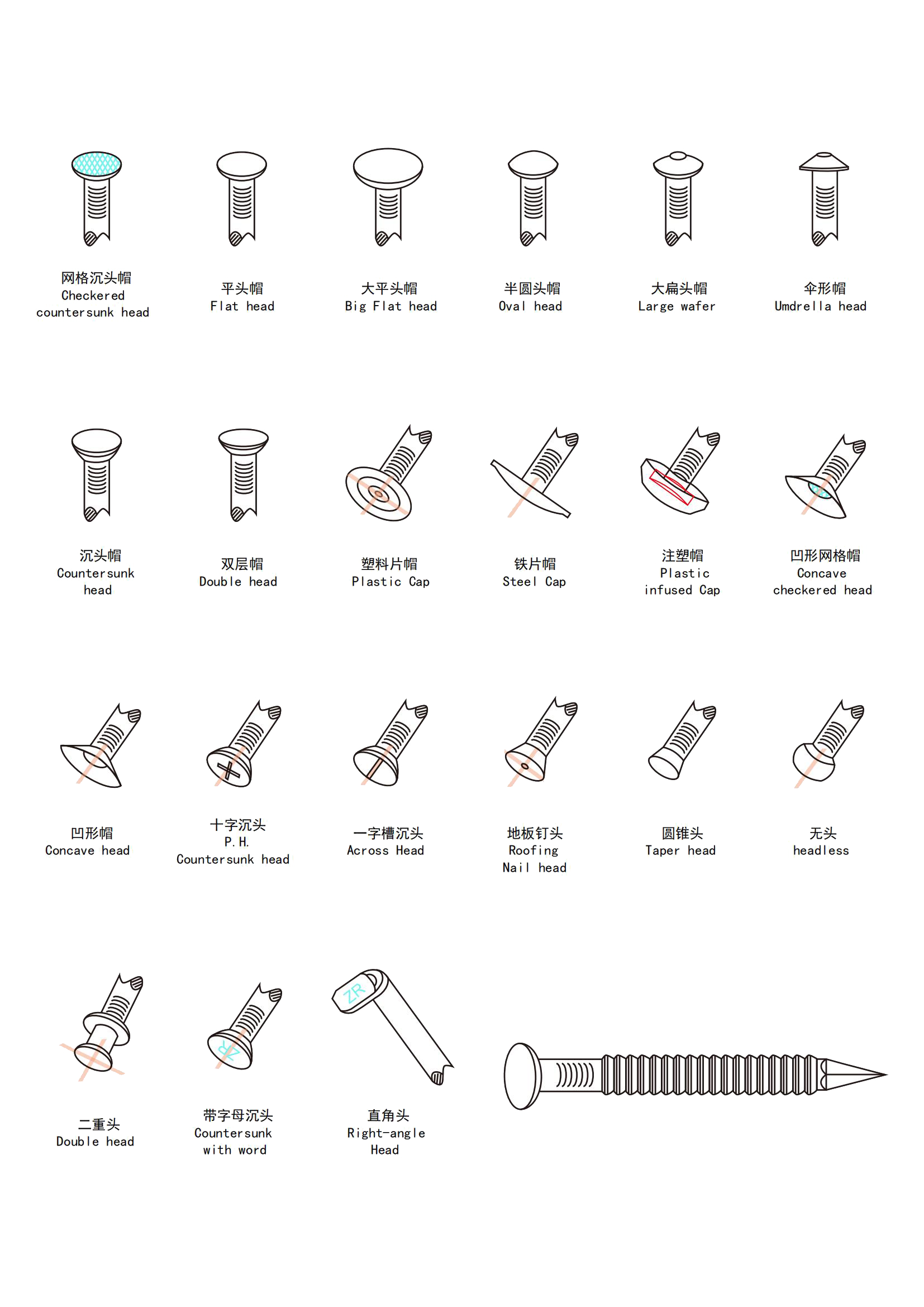

Mofuta le Sebopeho sa Hlooho ea Manala

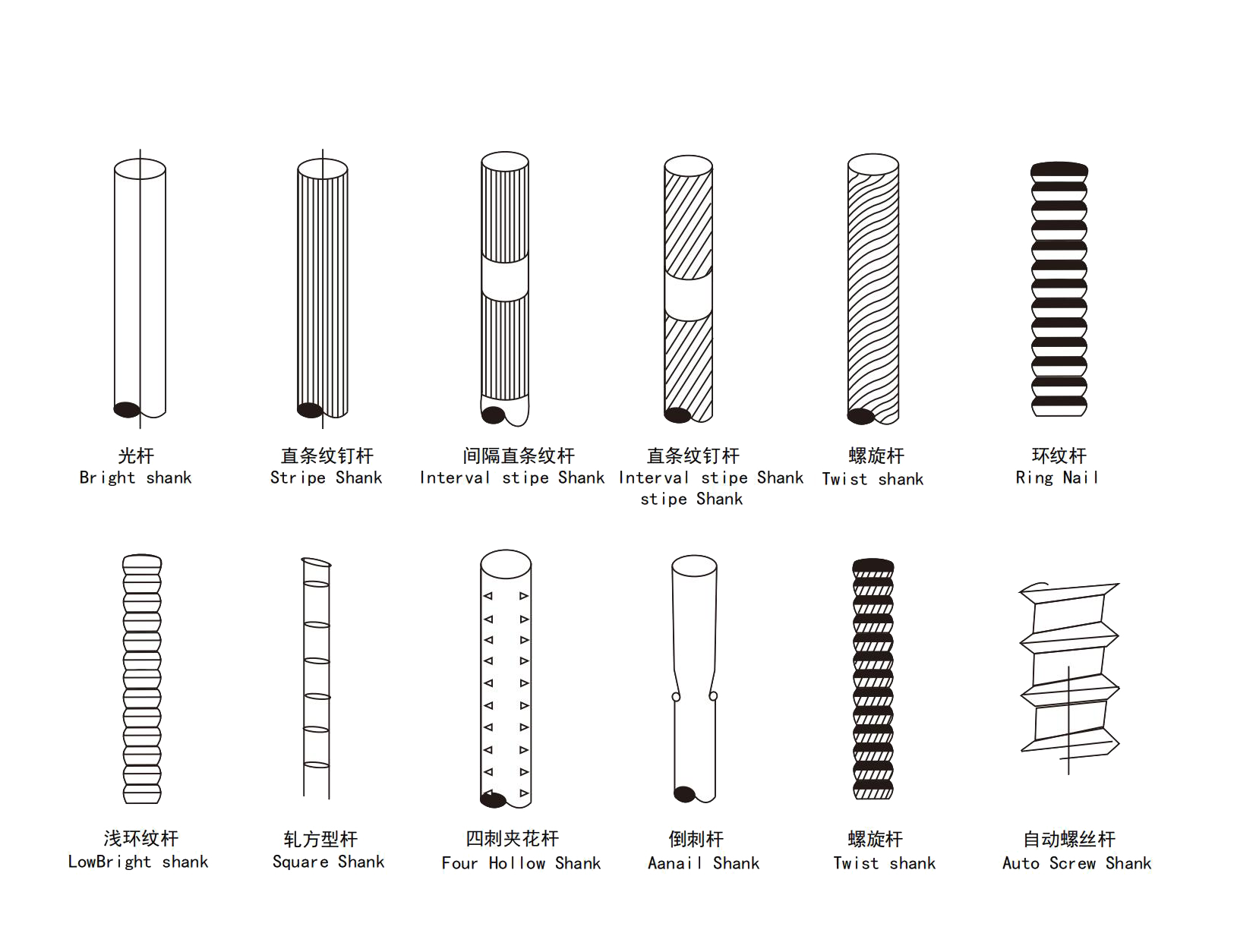

Mofuta le Sebopeho sa Sekotjana sa Manala

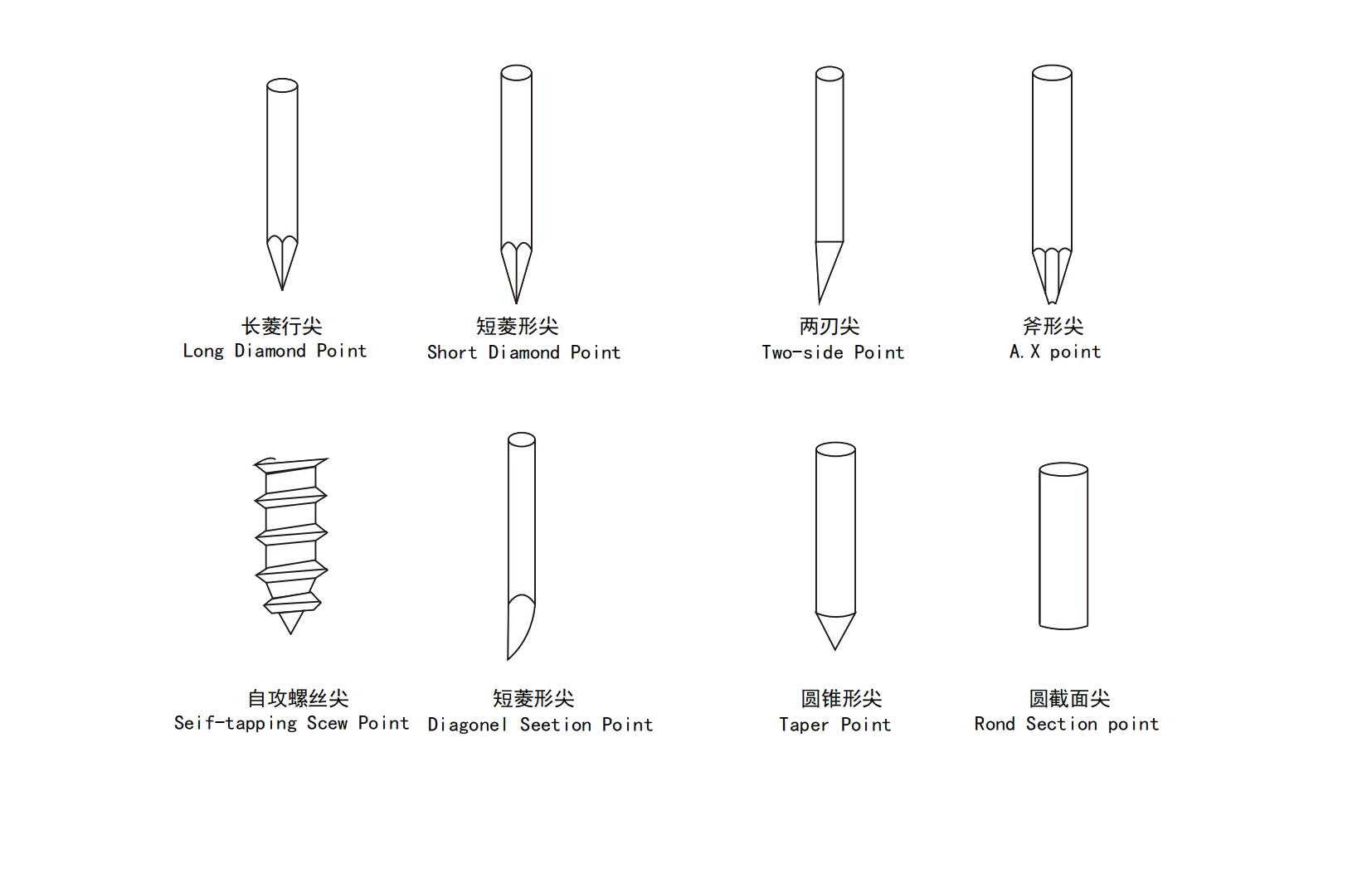

Mofuta le Sebopeho sa Manala Ntlha

Yihe Enterprise ke khamphani e ikgethileng ka moralo le tlhahiso ya manala, manala a sekwere, di-nail roll, mefuta yohle ya manala le di-screw tse bōpehileng ka tsela e ikgethang. Khetho ya di-nail tsa tshepe ya carbon ya boleng bo hodimo, koporo, aluminium le tshepe e sa ruseng, mme e ka etsa galvanized, hot dip, black, koporo le kalafo e nngwe ya bokahodimo ho ya ka tlhoko ya bareki. Sekuru se seholo ho hlahisa di-screw tsa mochini tse entsweng US ANSI, BS machine screw, bolt corrugated, ho kenyeletswa 2BA, 3BA, 4BA; di-screw tsa mochini tse entsweng Jeremane DIN (DIN84/ DIN963/ DIN7985/ DIN966/ DIN964/ DIN967); GB Series le mefuta e meng ya dihlahiswa tse tloaelehileng le tse sa tlwaelehang tse kang di-screw tsa mochini le mefuta yohle ya di-screw tsa mochini wa koporo.

Sehlahisoa sa rona se ka sebelisoa thepa ea ka tlung ea ofisi, indastering ea likepe, tereneng, kahong, indastering ea likoloi. Ka lits'ebetso tse pharaletseng tse loketseng mafapha a fapaneng, sehlahisoa sa rona se ikhetha ka boleng ba sona bo ikhethang—se entsoe ka thepa ea boleng bo holimo le mekhoa e tsoetseng pele ea tlhahiso ho netefatsa ho tšoarella le ts'ebetso e ntle ka ho fetisisa. Ho feta moo, re boloka thepa e ngata ka linako tsohle, e le hore u ka natefeloa ke ho tlisoa kapele le ho qoba tieho mererong ea hau kapa ts'ebetsong ea khoebo, ho sa tsotelehe bongata ba odara.

Ts'ebetso ea rona ea tlhahiso e hlalosoa ke boqhetseke bo botle haholo—e tšehelitsoe ke theknoloji e tsoetseng pele le litsebi tsa mesebetsi ea matsoho tse nang le boiphihlelo, re ntlafatsa mohato o mong le o mong oa tlhahiso ho netefatsa ho nepahala le bokhabane sehlahisoa se seng le se seng. Re tiisa melaoana e thata ea taolo ea boleng e sa sieeng sebaka sa ho sekisetsa: thepa e tala e hlahlojoa ka hloko, litekanyetso tsa tlhahiso li behiloe leihlo haufi-ufi, 'me lihlahisoa tsa ho qetela li hlahlojoa ka botlalo ka boleng. Re susumetsoa ke boinehelo ba bokhabane, re loanela ho etsa lihlahisoa tsa boleng bo holimo tse hlahelletseng 'marakeng ka boleng ba tsona bo phahameng le boleng bo tšoarellang nako e telele.